Have a specific question about your LBP project? Click below and let’s get started.

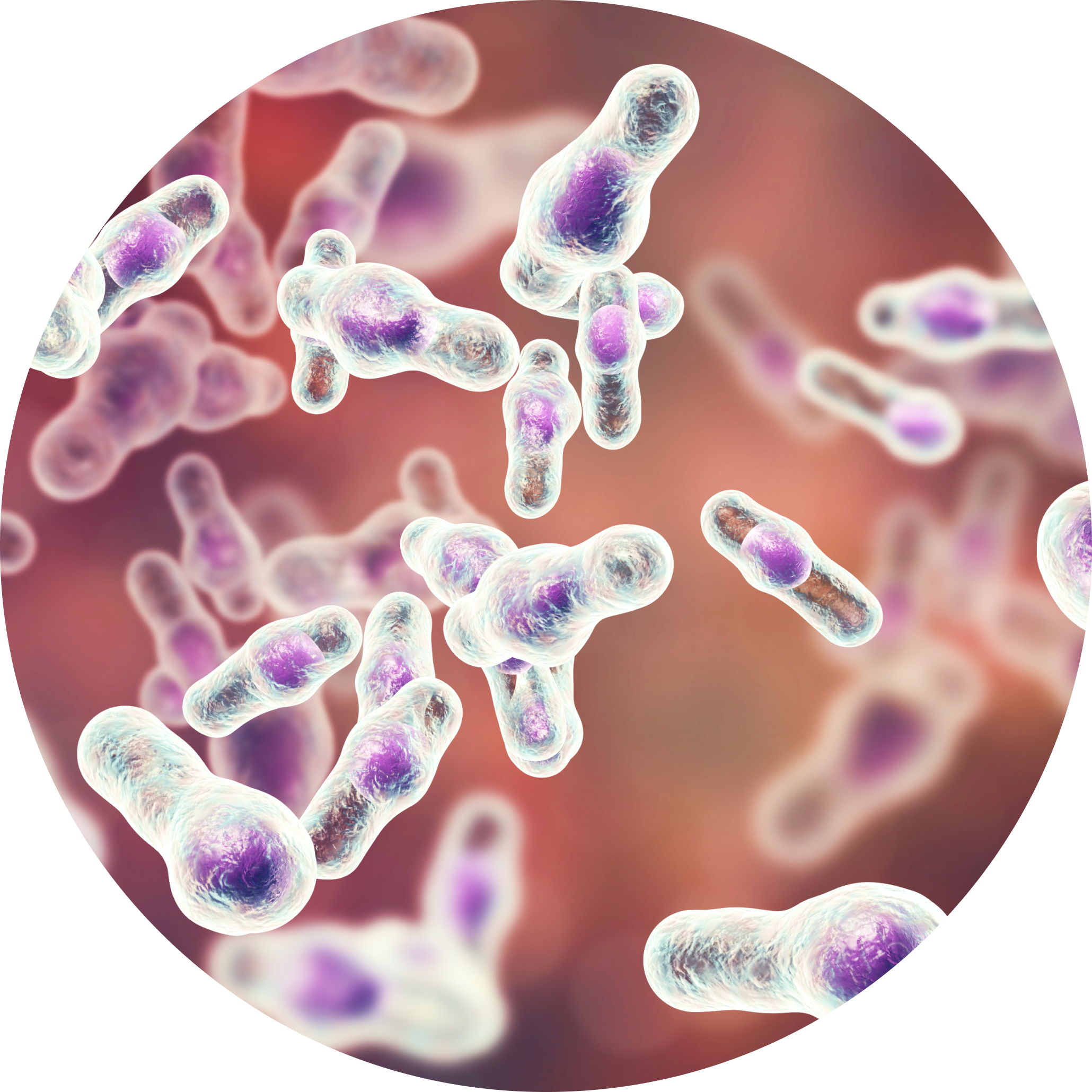

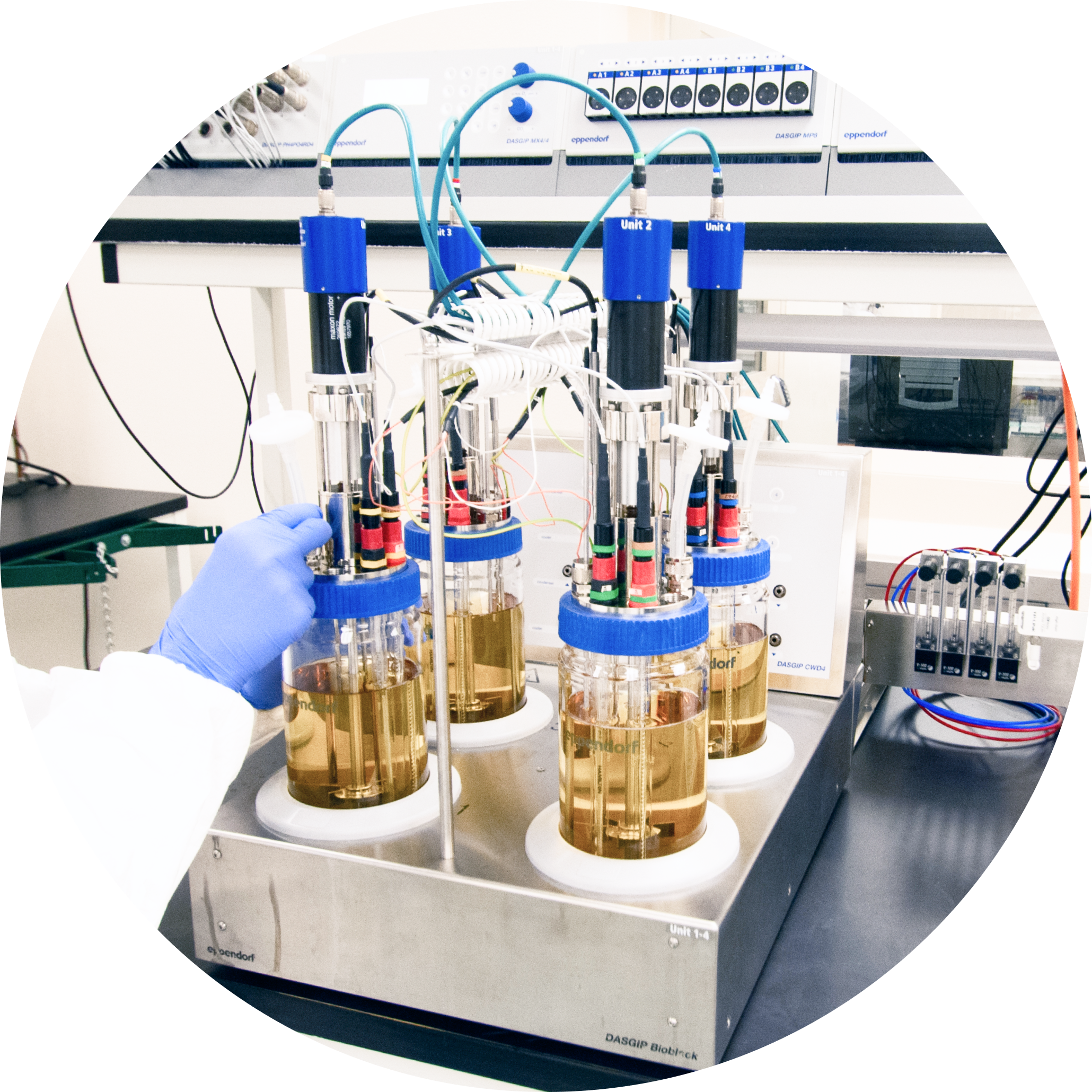

Reagent Grade and GMP Bacterial Toxins

List Labs has extensive experience manufacturing custom Reagent Grade and GMP bacterial toxin products for both Phase I and Phase II clinical trials.