Have a specific question about your LBP project? Click below and let’s get started.

Live Biotherapeutic Products

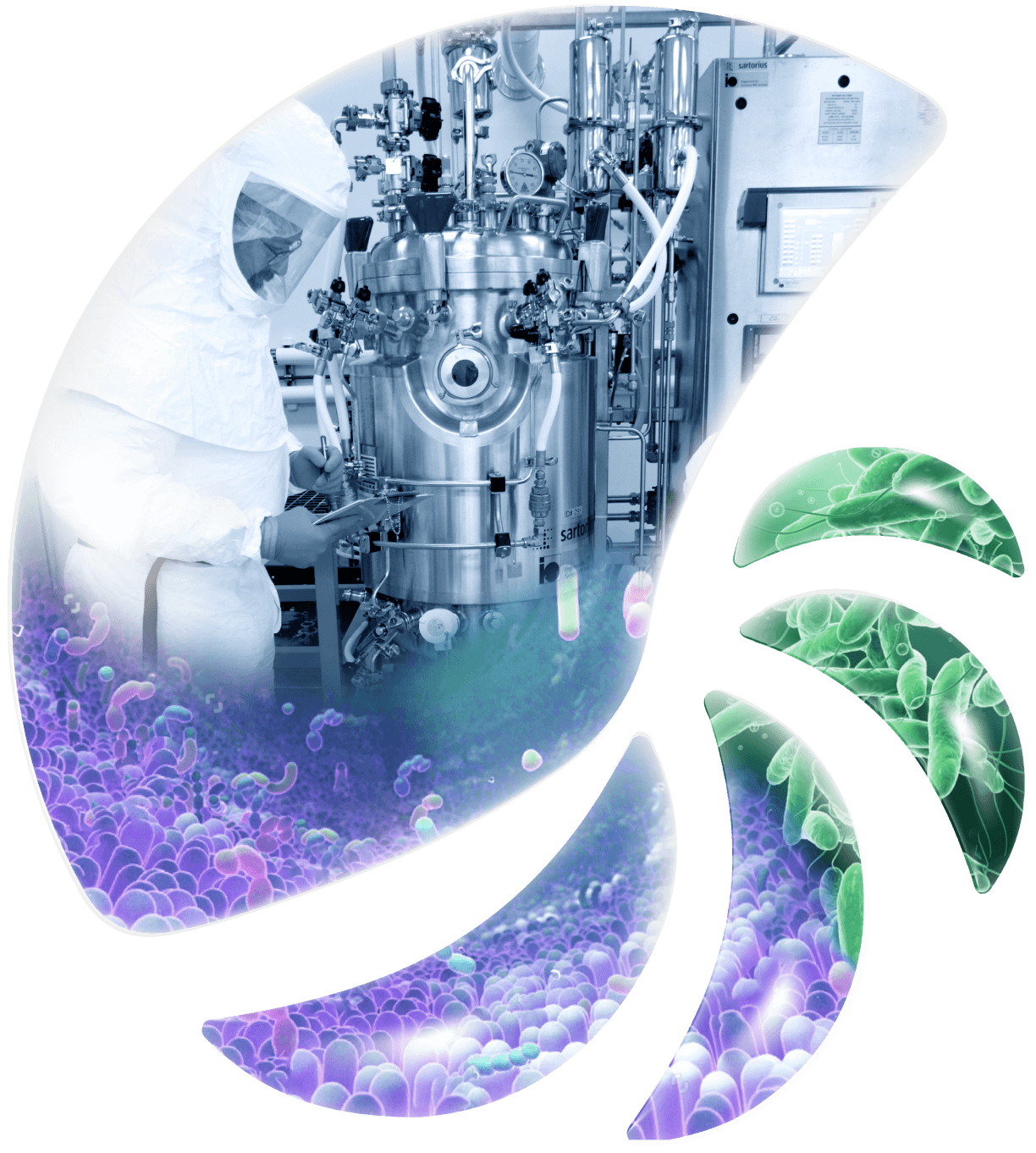

List Labs is one of the leading live biotherapeutic CDMOs providing LBPs, supporting innovators developing microbiome-based therapeutics.