Have a specific question about your LBP project? Click below and let’s get started.

I’d like to tell you about some of the obstacles you may encounter as you develop your live biotherapeutic product (LBP) and how List Labs can help you navigate through them.

Harnessing bacteria’s potential for a healthier world is our company mission. Our history and experience have been devoted to bacteria – what bacteria can produce – cultivating bacteria, purifying proteins, and polysaccharides. List Lab’s passion is to support innovators with quality bacterial products for research and development of vaccines and medical products and to perform contract development and manufacturing service for transformative therapies such as LBPs.

I am very excited to share that List Labs has partnered with BetterLife Pharma to develop and manufacture Altum Pharmaceutical’s novel and transformative therapeutic for the treatment of COVID-19. It is an honor to join in the fight against one of the greatest challenges of this decade.

Who is List Labs?

List is a privately held, woman-owned, and operated company in California, and about a quarter of our staff has advanced degrees. Initially, the core part of our business was manufacturing bacterial products. Beginning with selling one bacterial product in 1978, we now have over 100 stock products, including a GMP product. List Labs is a GMP-compliant facility, but we’re more than a collection of state-of-the-art equipment, List is much greater than the sum of its parts. Live biotherapeutic projects are not a cookie-cutter process and we are uniquely qualified to provide insight and flexibility to match the needs and requirements of each individual project. We typically take on 2 to 3 microbiome projects at a time, providing your project with individual attention and the critical advantage necessary to achieve a successful outcome.

Our cGMP compliant facility has 7 expertly designed manufacturing suites allowing segregation of product campaigns and spore containment if needed. The suites undergo treatment with vaporous hydrogen peroxide prior to GMP manufacturing to ensure the quality of your product. Due to the design of the facility and equipment options, we have the ability to manufacture several products in parallel.

Leveraging decades of experience cultivating a variety of microorganisms and GMP manufacturing experience for our products and partners, the transition to the microbiome space was a natural extension of our capabilities and expertise. We began a project about 7 years ago with a partner to develop and manufacture a live bacteria product. One of the first in the burgeoning microbiome field.

We have now worked on dozens of projects for indications in the gut, skin, women’s vaginal and urinary tract health, and CNS. We manufacture products for Phase I and II clinical trials. And we have produced over 20 different LBP products. These projects not only include manufacturing but also typically require a lot of development, many of which come straight from the academic bench with very little development past a shake flask or bottle cultivation. We are a partner who is invested in the success of your project and work as an extension of your team.

Let’s use climbing Mt Everest as an analogy. We are climbing the mountain with you, right alongside you. It’s a great analogy because it gets harder and harder the higher you get, and what you do at the bottom, your preparation will make or break you at the top. Aggressive timelines, budget constraints, these are the shear cliffs we can see but so many of the obstacles that await are unseen black ice, or bottomless crevasse’s… I know it’s a bit dramatic but getting a LBP to market is much the same, full of potential pitfalls.

So, today I want to share with you what some of these pitfalls look like and give you a glimpse of how List Labs can help you avoid becoming one of the many, that never realize the ultimate goal.

Source of Strain

If there is anything you take home from this talk, it should be this. “Choose Wisely!” Your choice of strain is made early in the project and changing mid-ascent even to “quote” the same species has a compounding impact. If you need to change strains, all of your in vivo and in vitro assay will need to be repeated along with all your development. The result can be very costly and cause a substantial delay to your timeline. A strain identified as a particular species is not equal to another strain identified as the same species. Each is unique and the characteristics or phenotypes that are important for your strain and indication may not be representative of another strain although identified as the same species.

But whatever your strain of choice is, it is highly likely that we have worked with it or a similar strain before. This is a sample list, although not exhaustive, of the strains we have worked with and of course not giving away any confidentiality of our clients.

Animal-Free Media Replacement

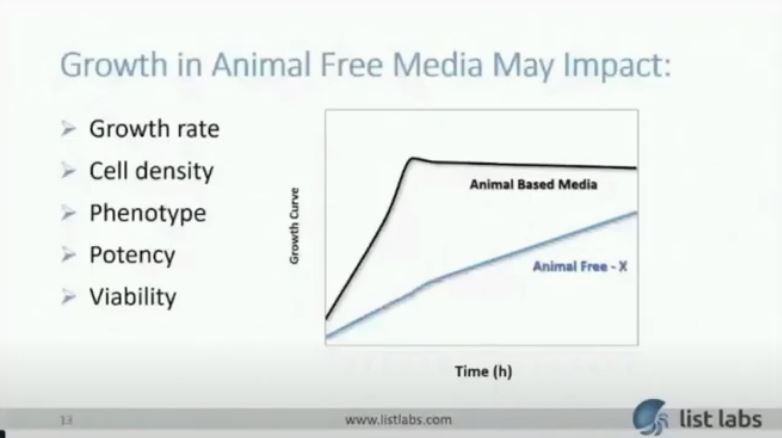

Another potential obstacle is replacing the media with animal-free alternatives. Since you need to establish a product that is BSE/TSE-free, many clients choose to switch to animal-free media. This is not trivial as there are many animal-derived components that are difficult to replace and are necessary for the robust growth of the organism. Shown in the graph below, is an animal-based media compared to an animal-free base media missing a critical animal-derived component which when the client came to us they had been unsuccessful in replacing. Growth in an animal-free media may impact growth rate, final cell density, phenotype (which may be an important characteristic for your indication), potency, and viability. All of which has implications to the scale of the process in order to have enough viable cells for your dose requirements. This directly impacts your Return on investment.

But we know how to tackle the problem. This is an example using the graph I showed you before where growth rate and final cell density were impacted without a very critical animal-derived component. Once we identified a suitable replacement, we demonstrated similar or better growth than with the animal-derived media. Then we realized further improvements in cell density with process improvements resulting in a 5-10X improvement in cell density.

Preserving Viability

Another pitfall is loss in viability of your organism through the process. This is a typical manufacturing process flow for a live biotherapeutic product. Initially, the strain is cultivated in a seed culture either anaerobically or aerobically and inoculated into the large vessel (such as a stainless steel bioreactor or single-use bioreactor), then harvested by tangential flow filtration, formulated, lyophilized, sieved, and then filled into vials, applicators, or formulated to fill capsules.

Different organisms will have different sensitivities to the process that may impact its viability including the growth phase at which the strain was harvested, the harvest process, and the environment during the harvest, or during the lyophilization, sieving, and encapsulation process. Understanding the viability of the organism throughout the process is important to know where to focus your development efforts.

We understand these risks and what tools we can use to improve the yield of the live organism at the end of your process. We have demonstrated substantial improvements in viability by 2 to 100 fold by optimizing these variables.

Scale Up

Another hurdle to overcome is the scale-up of the process. We often start with a process that is at the tube, bottle, or shake flask scale which requires a substantial amount of scale-up development. The process development of the cultivation and harvest should be performed in a scaled-down version of the process such that performance will be predictable at scale with the necessary process controls to demonstrate similar performance. List has 1L bioreactors and scaled-down versions of the harvest process so we can isolate specific variables and understand the impact on the process. We typically perform 10X scale up from 1L to 10L to the 100L process to minimize the surprises at scale and provide a robust process. Your timeline and costs for development should include these activities.

QC Analytical Development

An obstacle of the QC Analytical Development of your LBP is the development of the bioburden assays, USP<61>/<62> which is not straightforward with a live organism. For LBPs these assays need to be tailored and developed for each organism and we have experience working on these assays. We are also able to harness a lot of efficiencies for the customer by not only working on the manufacturing but also working on the analytical development in-house. Analytical assays are necessary for both in-process testing and final QC testing for release.

Is List Labs the right CDMO for your project?

As a novice climber, would you attempt to scale Mt. Everest with anything less than the most experienced Sherpa? We are a passionate and dedicated team with the expertise and experience that is critical to reach the summit. We have been there many times. We recognize the obstacles and while no two ascents are exactly the same, we have the flexibility to guide you to the top and deliver a quality product for the success of your project. We look forward to working with you!

If you have any questions, please contact us at services@listlabs.com or through our contact page.

By: Stacy Burns-Guydish, Ph.D., President

Check out the Overcoming Obstacles in the development of Live Biotherapeutic Products video!

By: Mary N. Wessling, Ph.D. ELS

What is Lyophilization?

Protecting the activity of enzyme products and the viability of bacterial cultures that are used in scientific experimentation is an area where List Biological Laboratories is a leader. Lyophilization has been the most extensively used technique for maintaining the integrity of biopharmaceuticals. Lyophilization (otherwise known as freeze drying) is a sublimation process: the liquids in the product go from a frozen state to a gaseous state without going through a liquid phase, leaving behind dry solids.

The Steps of Lyophilization

The lyophilization cycle proceeds through three steps:

- freezing, in which the product is brought to a temperature below its freezing point at a rate that produces water crystals of ideal size;

- primary drying, during which the crystals undergo sublimation under vacuum;

- secondary drying, which removes residual water vapor after the primary drying. Finally, the lyophilized product may be sealed in an inert gas atmosphere.1

Why Lyophilization is Important

Lyophilized formulations of biopharmaceuticals must be approached based on the specific vulnerability of the original product. List Labs is very experienced in producing lyophilized products; most of our stock products and many of the products produced through our GMP Contract Manufacturing services are lyophilized. To ensure activity and viability, List Labs evaluates the use of various sugars, proteins, small molecules, polymers, and salts in candidate formulations. Also, the products can be aliquoted into vials and lyophilized, which makes for increased efficiency of use and preserves the integrity of the product when used in experimental studies over some time. The demands for quality and safety of biological products, such as vaccines, are very stringent;2 the FDA document regarding lyophilization of parenterals provides a useful overview of the lyophilization process from a regulatory point of view. List Labs’ lyophilized products have been used in a wide range of experimental procedures for more than thirty years.

References

- Chang BS, Reilly M, Chang H. Lyophilized Biologics. In: Varshney D, Singh M, eds. Lyophilized Biologics and Vaccines. New York: Springer; 2015:93-119.

- Bloom BR, Lambert P-H, eds. The Vaccine Book. 2 ed. Amsterdam, Boston: Elsevier Academic Press; 2016:90-92. PMCID: PMC3323310

By: Stacy Burns-Guydish, Ph.D., Senior Director, Microbiology

The human body is home to a vast ecosystem of microbes, called the microbiome. Research is shedding light on the importance of the microbiome as a benefactor to our health and development. Perturbation of the microbiome has been associated with a growing number of diseases including inflammatory bowel disease, allergies, asthma, autism, and cancer.

Microbiome Bacteria as Potential Therapy

Commensal bacteria of the microbiome are thought to be potential therapies for prevention or treatment of infections such as Clostridium difficile, acne, and bacterial vaginosis. Live biotherapeutic products (LBP) manufactured from commensal bacteria are being investigated by many companies and several clinical trials are underway.

Anaerobic Cultivation & Containment Required for Microbiome Research

Many of these commensal microorganisms for the manufacture of LBP are obligate or strict anaerobes and spore forming organisms, presenting unique challenges to the emerging microbiome therapeutic space. Expertise and proper equipment for anaerobic cultivation and proper containment of spore forming organisms is lacking in the industry and only a handful of contract manufacturing companies have the capabilities to perform GMP manufacturing anaerobic organisms, creating a bottleneck.

An alternative for companies is to build their own GMP facility, as Seres Therapeutics has done. But start-ups typically do not have the funds to build their own facilities thus the CMO backlog impacts timelines. Most CMO’s quote a wait of 9-12 months for projects to begin. So how will these burgeoning companies meet their aggressive timelines to produce their LBP for clinical trials?

Questions to Ask Partner GMP Labs

If you are a startup, sound advice is to start conversations now with potential CMOs and find out if their capabilities align with your organism cultivation requirements and specifications.

- How many Live Biotherapeutic Products have they produced and released?

- What is their experience with anaerobes?

- Can they work with spore formers?

- What are their QC and QA capabilities and regulatory support?

- What scale production is possible?

List Labs Is well suited to Partner in GMP Microbiome Research

List Biological Laboratories, a boutique contract manufacturing company, has the expertise and infrastructure for manufacturing both obligate and strict anaerobes and spore forming organisms. List has over 30 years’ experience cultivating anaerobic organisms. We have produced master and working cell banks and LBP for several customers currently in Phase 1 and 2 clinical trials. In addition, we have expertise in the development of the non-trivial required purity/bioburden assays, including USP61 and UPS62, for testing and release of these unique live microorganism products.

Contact List Labs to get your microbiome research project off the ground today.